LIGHT DUTY STEEL-TO-STEEL

Diameter / Thread Form: 8 – 18, 10 – 16

Head Style: Hex Washer Head (HWH), Socket Pan Head (SP), Modified Truss Head (MTH)

Drill Point: Teks 2 & Teks 3

Finish: Electro-Zinc, Climaseal Coating, Climaseal+ Coating

- Sharp convex drill point has precise cutting edges to improve drill performance with less effort

- Non-walking point provides fast material engagement

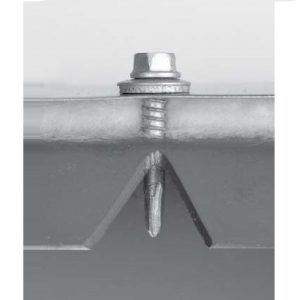

- Unique point to thread design extrudes the metal preventing strip-out

- Point to thread design maximizes pullout performance and minimizes backout

- Three head styles available to handle various applications

- Climaseal® finish provides excellent corrosion resistance

MEDIUM DUTY STEEL-TO-STEEL

Diameter / Thread Form: 10 – 16, 12 – 14, 1/4 – 14

Head Style: Hex Washer Head (HWH)

Drill Point: Teks 2 & Teks 3

Finish: Electro-Zinc, Climaseal Coating, Climaseal+ Coating

- Point has precise cutting edges to improve drill performance with less effort

- Non-walking point provides fast material engagement

- Point to thread design maximizes pullout performance and minimizes backout

- Drills and taps in the broadest range of applications

- Climaseal® finish provides excellent corrosion resistance and lower tapping torque

HEAVY DUTY STEEL-TO-STEEL

Diameter / Thread Form: 12 – 24, 1/4 – 28

Head Style: Hex Washer Head (HWH)

Drill Point: Teks 4 & Teks 5

Finish: Climaseal Coating

- Unique double fluted point has precise cutting edges to improve drill performance in 1/4″ thru 1/2″ steel

- Engineered for fast drilling and smooth tapping with less effort

- Climaseal® finish provides excellent corrosion resistance and lower tapping torque

- Attachments up to 7.2″ of material including 1/2″ steel

- 1/4″ Diameter has notched threads to reduce tapping torque

To view our full performance tables, click here; and for our full selection chart, click here. (will open a new tab)

LIGHT DUTY STEEL-TO-STEEL APPLICATIONS

- Stitch roof deck and wall panel sidelaps

- HVAC, electrical trim accessories to steel framing

- Residential steel frame construction

- Brick ties to steel framing

- Track to stud and stud splicing

- Hat channel to stud

MEDIUM DUTY STEEL-TO-STEEL APPLICATIONS

- Roof deck to steel framing

- Wall panel to girt

- Duct work to steel framing

- Accessories to steel framing

- Clip to steel framing

- Retrofit framing

HEAVY DUTY STEEL-TO-STEEL APPLICATIONS

- Metal deck to structural steel or bar joist

- Clips to structural steel or bar joist

- Liner panels to structural steel or bar joist

- Accessories to structural steel or bar joist

- Longer length fasteners can be used in retrofit clip and sheet applications

1. A standard screwgun with a depth sensitive nosepiece should be used to install Teks. For optimal fastener performance, the screwgun should be a minimum of 4 amps and have a RPM range of 0-2000.

2. Adjust the screwgun nosepiece to properly seat the fastener.

3. New magnetic sockets must be correctly set before use. Remove chip build-up as needed.

4. The fastener is fully seated when the head is flush with the work surface.

5. Overdriving may result in torsional failure of the fastener or stripout of the substrate.

6. The fastener must penetrate beyond the metal structure a minimum of 3 pitches of thread.

LIGHT DUTY STEEL-TO-STEEL

A Available in A PAK, X Available in X PAK, + (CL+) Coating

MEDIUM DUTY STEEL-TO-STEEL

A Available in A PAK, X Available in X PAK, + (CL+) Coating

HEAVY DUTY STEEL-TO-STEEL

P Available in P PAK, X Available in X PAK

- Factory Mutual (J.I. 2 X 9A2 AM)

- ICC – ESR 1976