2 x 4 headers to steel frames

Plywood fascia to steel frames

Plywood roof and floor sheet to steel frames

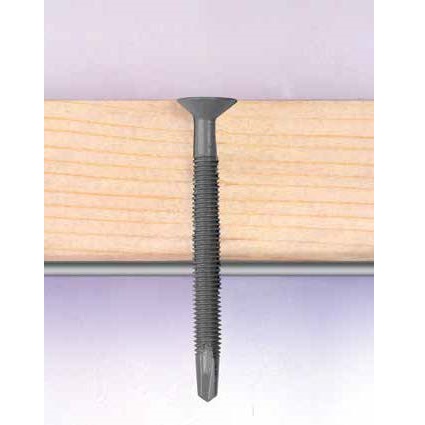

NO PRE-DRILLING, FAST, EFFICIENT ATTACHMENT OF WOOD TO METAL

Teks Wood-to-Metal Screws provide secure wood to metal fastening with strong holding power, without the need to pre-drill. The drill-point and flute are designed to remove material efficiently and properly size the hole for self-tapping threads. Special wings ream a hole in the wood to prevent thread engagement during drilling. Teks Wood-to-Metal Screws are ideal for attaching roof/subfloor decking, trailer beds to frame, and wood headers to steel frame.

Diameter/Thread Form: 10 – 24, 12 – 14, 1/4 – 20

Head Style: Socket Wafer Head (SW), Philips Flat Head (PFH)

Drill Point: Teks 3 & Teks 4

Finish: Electro-zinc, Grey Specx Coating

To view our full performance tables, click here; and for our full selection chart, click here. (will open a new tab)

2 x 4 headers to steel frames

Plywood fascia to steel frames

Plywood roof and floor sheet to steel frames

1. A standard screwgun with a depth sensitive nosepiece should be used to install Teks. For optimal fastener performance, the screwgun should be a minimum of 6 amps and have an RPM range of 0 2500.

2. Adjust the screwgun nosepiece to properly seat the fastener.

3. Worn or damaged bit tip should be replaced.

4. The fastener is fully seated when the head is flush with the work surface.

5. Overdriving may result in torsional failure of the fastener or stripout of the substrate.

6. The fastener must penetrate beyond the metal structure a minimum of 3 pitches of thread.

7. All #10 diameter “Winged” parts must be driven into a minimum of 16 GA steel thickness.

8. All 1/4 and #12 diameter “Winged” parts must be driven into a minimum of 1/8″ steel in order to break the wings consistently.

Finish: Electro-zinc Plating. With Wings. |

|||||||||

| PART NUMBER | REFERENCE NUMBER | DESCRIPTION | HEAD STYLE | DRILL POINT | DRILL & TAP CAPACITY | WOOD ATTACHMENT RANGE | BOX QTY | “P” PAK QTY | “X” PAK QTY |

| 21380 | 21380 P B | 10-24 x 1-1/2" | #2 SW | #3 | .036-.175 | 1/4"-1" | 3000 | - | - |

| 21730 P | 21730 P | 12-24 x 2" | #3 SW | #4 | .125-.250 | 1/4" - 1" | 2000 | 100 | - |

| 21750 | 21750 P | 12-24 x 2-1/2" | #3 SW | #4 | .125-.250 | 1/4"-1-1/2" | 1500 | - | 100 |

| 21751 P | 21751 P | 12-24 x 3" | #3 SW | #4 | .125-.250 | 1/4"-2" | 1000 | - | 100 |

Finish: Electro-zinc Plating. Without Wings. |

|||||||||

| PART NUMBER | REFERENCE NUMBER | DESCRIPTION | HEAD STYLE | DRILL POINT | DRILL & TAP CAPACITY | WOOD ATTACHMENT RANGE | BOX QTY | “P” PAK QTY | “X” PAK QTY |

| 21320 | 21320 | 10-24 x 1" | #2 SW | #3 | .036-.175 | 1/4"-1/2" | 5000 | - | - |

Finish: Gray Spex Coating. With Wings. |

|||||||||

| PART NUMBER | REFERENCE NUMBER | DESCRIPTION | HEAD STYLE | DRILL POINT | DRILL & TAP CAPACITY | WOOD ATTACHMENT RANGE | BOX QTY | “P” PAK QTY | “X” PAK QTY |

| 1980 | 1096000 | 1/4-20 x 3" | #3 PFH | #4 | .125-.250 | 3/4"-2" | 1000 | - | - |

| 1092057 | 1092057 | 12-24 x 2-1/4" | #3 PFH | #4 | .125-.250 | 3/4"- 1-3/8" | 2000 | - | - |

| 1094056 | 1094056 | 12-24 x 2-3/4" | #3 PFH | #4 | .125-.250 | 3/4"-2-5/8" | 1600 | - | - |

X Available in X PAK, A Available in A PAK, P Available in P PAK